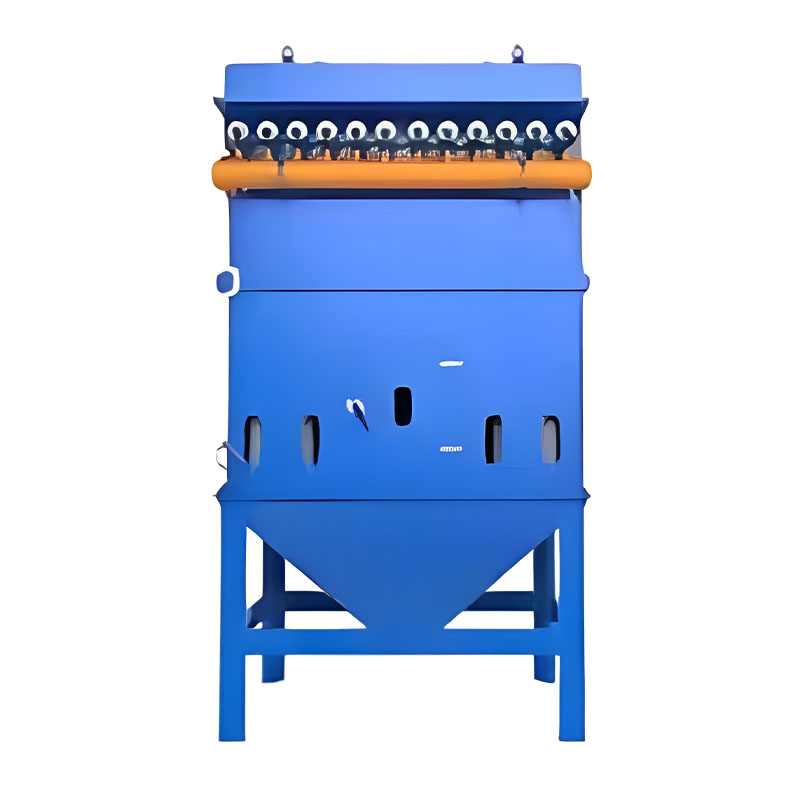

Dust Collector

Type 1000Processing customization

A dust collector is a device that separates dust from flue gas, also known as dust removal equipment. As a highly efficient air purification device, dust collectors play an important role in many fields. When choosing a dust collector, you need to consider multiple factors to ensure that the selected equipment can meet actual needs and have good performance and cost-effectiveness.

-

1. Product Description

Industrial environmental dust collectors are usually composed of air inlet, filtration system, dust cleaning system, exhaust port and other parts. The core is to capture dust particles in the air through filter materials, and regularly clean the dust on the filter materials through the dust cleaning system to ensure the continuous and efficient operation of the dust collector.

The working principles of dust collectors are diverse, including mechanical vibration, pulse blowing, back-blowing, etc., to meet the dust removal needs under different working conditions. At the same time, the dust collector also has an intelligent control system that can automatically adjust the cleaning frequency according to the on-site dust concentration, which not only ensures the dust removal effect, but also avoids unnecessary energy waste.

Industrial environmental dust collectors are widely used in dust pollution control in steel, cement, chemical, electric power, machinery and other industries, effectively reducing the dust concentration in the air, improving the working environment, reducing the risk of occupational diseases for workers, and also injecting strong green power into the sustainable development of enterprises.2. Specifications

The specifications of industrial environmental dust collectors vary depending on product type, application scenario and customer needs

Processing air volume:

Processing air volume refers to the volume of dust-containing gas that the dust collector can handle per unit time, usually in cubic meters per hour (m³/h). Different models of dust collectors have different processing air volumes and can be selected according to actual needs.

Filter area:

The filter area refers to the total area of the filter material inside the dust collector, usually in square meters (㎡). The size of the filter area determines the dust removal efficiency and processing capacity of the dust collector.

Equipment size:

The equipment size includes the length, width, and height of the dust collector, which can be selected according to the on-site installation space. Different models of dust collectors have different sizes and need to be customized according to actual conditions.

Inlet dust concentration:

The inlet dust concentration refers to the concentration of dust particles in the dust-containing gas at the inlet of the dust collector, usually in milligrams per cubic meter (mg/m³). The dust collector needs to be designed according to the inlet dust concentration to ensure the dust removal effect.

Outlet dust concentration:

Outlet dust concentration refers to the concentration of dust particles in the dust-laden gas at the outlet of the dust collector, and is also an important indicator for measuring the performance of the dust collector. The outlet dust concentration of different models of dust collectors is different, and it needs to be selected according to actual needs.

Cleaning method:

Cleaning method refers to the method by which the dust collector cleans the dust accumulated on the filter material, including mechanical vibration, pulse jet, back-blowing, etc. Different cleaning methods are suitable for different working conditions and dust characteristics.

Control system:

The control system refers to the intelligent control part of the dust collector, including sensors, controllers, actuators, etc. Through the control system, the dust collector can automatically adjust the cleaning frequency according to the on-site dust concentration to achieve intelligent operation.

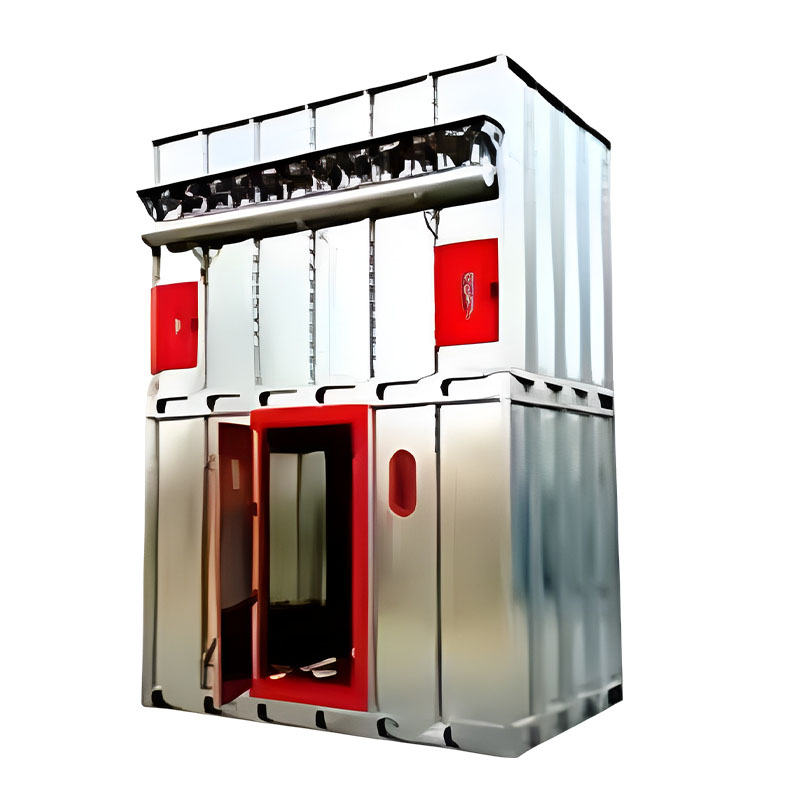

Material and structure:

The material and structure of the dust collector need to be selected according to the use environment, dust characteristics and customer needs. Common materials include metal materials such as carbon steel and stainless steel, and non-metallic materials such as fiberglass. In terms of structure, the dust collector can be vertical, horizontal and other forms.